說明:

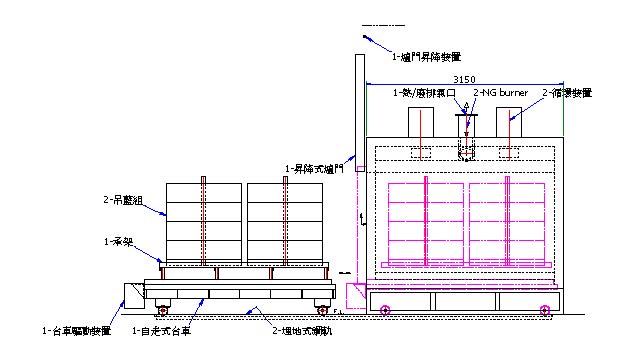

使用目的:AC件之退、淬火

歡迎洽詢訂製!

規格尺寸:

| 使用溫度 | 均溫性能 | 加熱機制 | 輸送 | 批次式 | 爐氣氛 |

| Max 600℃ | ±5~8℃ | 熱風 | 油壓絞盤 | 可選用 | 大氣 |

T6 Aluminum Heat Treatment

Features

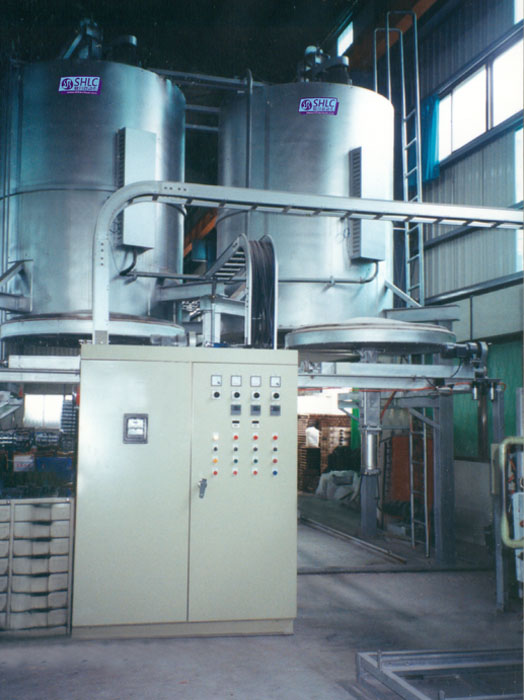

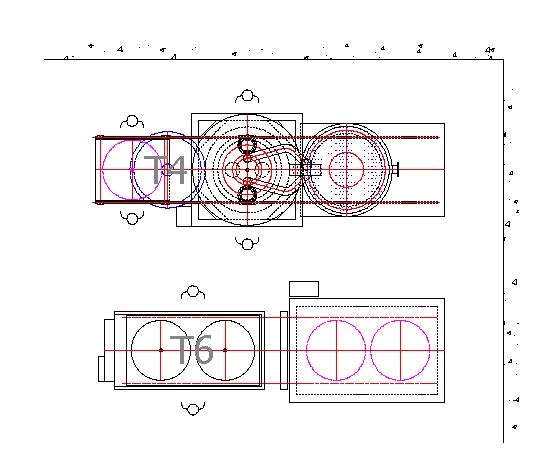

- Equipment consists

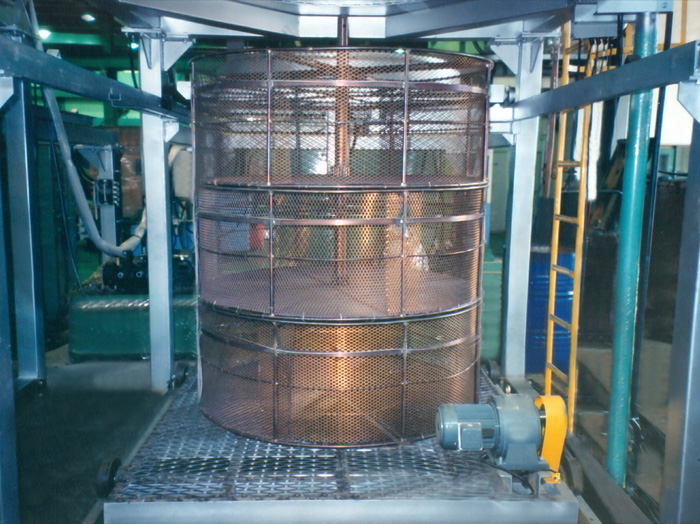

- Loading Table

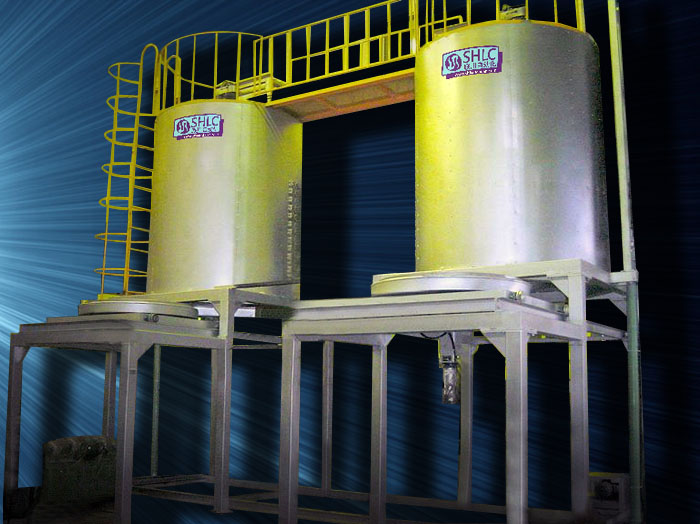

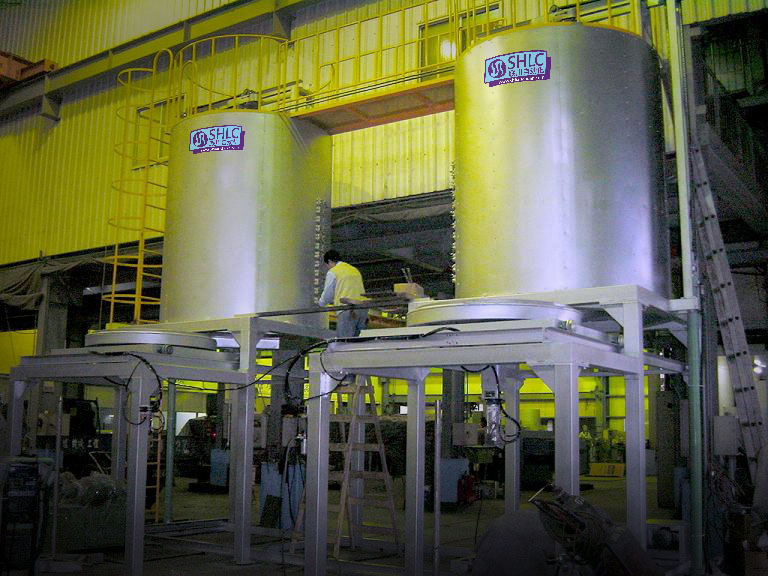

- Solution Furnace

- Quenching Tank (water, etc)

- Aging Furnace

- Unloading Table

- Transfer Car (Optional)

- Baskets return system (Optional)

- Cooling Chamber (Optional)

Applications

- Heat treatments of aluminum die-casting process

- Aimed at industrial sectors such as Automotive parts, Railway, Electric and energy, Marine etc.

Specifications

- Option Items: Transfer car

Automatic basket positioning systems

Automatic load feeding devices

Operation Sequence:

- Baskets with parts to be heat treated are positioned on the loading table just in front of the Solution Furnace.

- When discharge operation starts, the Solution Furnace rear door is opened and the last basket is driven out towards quenching position.

- Solution Furnace rear door is closed and lifting mechanism takes the mentioned basket down to the quenching bath. After that, Solution Furnace front door is opened and a new basket is driven into the Furnace being moved all the existing baskets inside the Furnace at the same time.

- Once quenching process is finished, basket is lifted up to initial position and driven just in front of Aging Furnace, waiting for permission to be loaded.

- On completion of aging process, Ageing Furnace rear door is opened and the last basket is driven out towards unloading table.

- Then Ageing Furnace rear door is closed, and afterwards front door is opened so as to let basket be loaded into the Furnace being moved all the existing baskets inside the Furnace at the same time.

- The system is completely automatic with limit switches and position detectors for controlling basket movements along the whole process.

其它說明: